Vacuum moulding is a manufacturing method to create a new product from a flat plastic plate. This product can be a workpiece carrier, bin or a lid.

How does it work?

This is how vacuum moulding works :

- The plate is contained in the machine, heated and inflated as an air bubble.

- Then the mold rises and the air is sucked out of the machine. The plastic joins the mold.

- After the product has cooled down, the plastic retains the shape of the mould and a new product is born.

- The product, such as a tray, is disconnected from the plate with a punch knife, ribbon saw or mill.

- The remaining plate material is shredded to extrude new plates.

Applications

Vacuum formed packaging is often used as a product carrier, tray or container for supplying the manufacturing industry. Vacuum-formed interiors position and protect the parts to be transported.

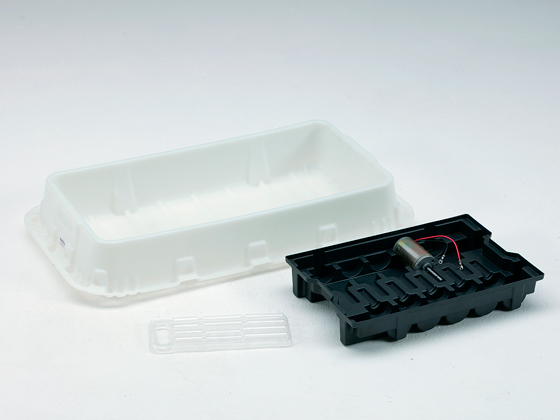

In the classic way, plastic transport bins with vacuum formed interieurs are used as product carriers. The solid plastic bin ensures stacking, the vacuum-formed interior positions and protects the parts to be transported. It is relatively expensive, you have to produce twice for a single package. That is why we have invested in vacuum forming molds with spare parts, which combine both functions.

Favorable price

Because of the forces the vacuum molds have to withstand are a fraction of the moulds for injection moulding, they are also about 80% cheaper. Vacuum moulding are usually cost-efficient for series from 250 units. The options for vacuum forming packaging are diverse. We would be happy to discuss your ideas with you.

Material

All materials that become plastic when heated (thermoplastics) can be used in the thermoforming process. The choice of the type of plastic mainly depends on the application.

We use polyethylene (PE) or polypropylene (PP) to make tough, impact-resistant products. HDPE is fall-resistant and virtually unbreakable, for example used for the luggage tray for Amsterdam Airport to transport 'difficult' luggage such as beauty cases or backpacks on conveyor belts without any problems.

When rigidity and precision of the mold are important, we usually choose (recycled) ABS or PET. Because ABS can be deformed very accurately, it is possible to make detailed shapes for smaller products, such as LED lights or difficult shapes such as gears and electronics.