Bespoke pallets

Plastic Pallets - Customised

If existing pallets are not sufficient, we manufacture them ourselves, both in steel and plastic. In consultation with the customer, we arrive at the best solution. Engels has extensive experience in adapting existing pallets to the specific requirements of the customer. In combination with specially milled parts, we produce complex custom pallets for various applications. Additionally, we can supply pallets suitable for use in cleanrooms, meeting the stringent hygiene standards required in these environments. Below you will find some examples of customer cases where Engels has designed and assembled customised pallets.

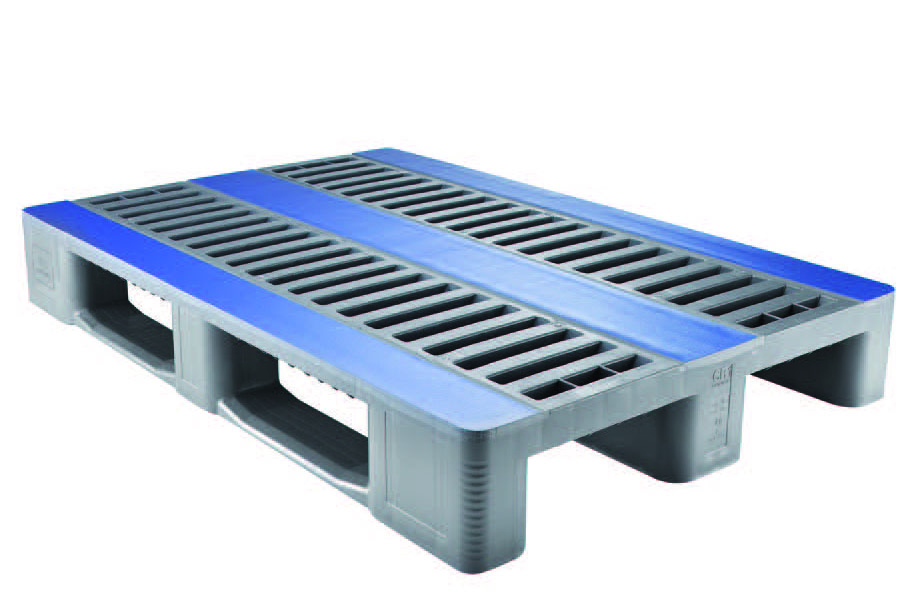

Plastic Pallets - Standard Modifications

To meet the needs of our customers without requiring large investments, many pallets from our delivery programme can be equipped with standard modifications such as raised edges and centre crosses for stable positioning of the load. We can also fit the top deck with welded anti-slip strips. For higher load capacity, internal steel profiles can be added to the pallets during the production process, or they can be equipped with extra runners. We are also happy to personalise the pallets with your logo or text using screen printing, branding, or in-mould labelling, which is also suitable for RFID tagging.

Anti-slip strips

Steel reinforcement

Prints

Raised edges

In-mould labeling

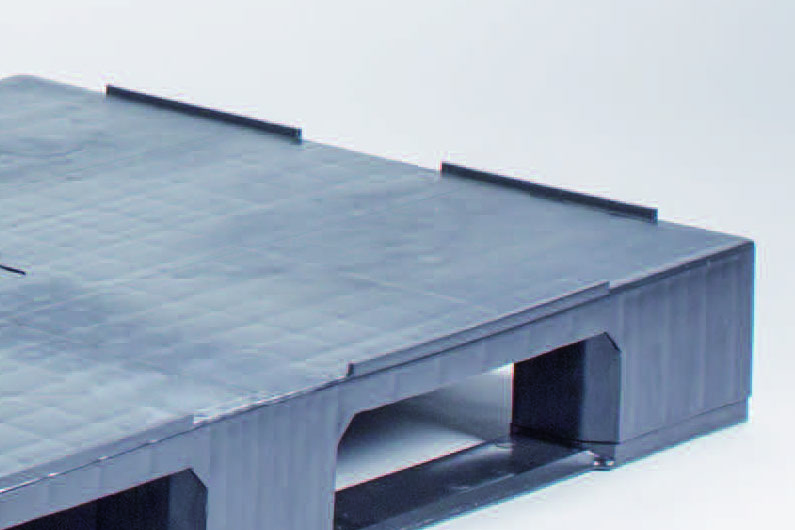

Plastic pallets - Custom dimensions

Existing pallets can be resized, with parts added or removed as needed. Our production department has extensive expertise in milling, sawing, welding, gluing, and stapling various types of plastic. We have the production facilities, materials, and resources to deliver customised pallets with varying lengths, widths, and shapes, whether in small quantities or large series productions.

Benefits of mirror welding:

- Custom Sizes Available: Adjustments in both height and length, whether shorter or longer.

- Strong weld: The weld is stronger than the surrounding material.

- Reproducibility: manual welding can result in variations between products. Mirror welding produces identical products.

- Cost-Efficient: A fully customised product can be created in a relatively short time.

Curious about the possibilities?

Contact us and discover the customised solutions available for your specific application.